Project Overview

This project tackles the unique challenge of habitat temperature regulation for future Martian missions. Utilizing thermoelectric generators, 3D-printed components, and open-source control systems, it aims to provide practical solutions for off-world sustainability.

Project Inspiration

Mars is a very interesting problem in that conventional HVAC ideas don’t really work: vapor-compression systems rely on refrigerants that can’t condense properly at Mars’s near-vacuum surface pressure of about 0.6 kPa (≈ 0.6 % of Earth’s sea-level atmosphere). Fans and radiators struggle because convective heat transfer is extremely weak in the thin CO₂ atmosphere, and the constant dust exposure and thermal cycling (from roughly −120 °C at night to +20 °C at midday) degrade seals, bearings, and coatings. With only about 40–45 % of Earth’s solar flux, you can’t simply scale a terrestrial heat pump. That pushed me to ask whether a mostly 3D-printed, recyclable system could capture daytime solar heat and release it after sunset in such a hostile environment.

Closer to home, the urgency is personal: build something robust and affordable enough to help heat my mom’s restaurant this winter. The HVAC fix isn’t feasible, so I’m aiming for a practical, safe add-on—mirrors for collection, a compact spiral heat exchanger, and simple smart controls—to cut fuel costs and keep staff and customers warm. Same idea, two frontiers.

Requirements and Constraints

Mission Goal

Mostly 3D-printed, solar-thermal heat-pump concept adaptable to ~0.6 kPa CO₂ and large thermal swings.

Environmental (Mars)

- Atmosphere: Near-vacuum → favor conduction/radiation, sealed flow paths.

- Thermals: Frequent cycling (−120 °C to +20 °C) → matched CTEs, low-temp toughness.

- Dust: Fine particulate → filtered intakes, protected bearings/seals, minimal exposed sliding parts.

- Solar flux: ~40–45% of Earth → maximize optical efficiency, downstream insulation.

Materials & Manufacturing

- Printability: PETG/ASA for structure; metal inserts for threads.

- Exchanger: Aluminum plate, spiral groove for 12 mm OD silicone tube, good contact pressure.

- Optics: Modular hex mirrors (~25 cm edge) on adjustable, lockable mounts.

- Hardware: Stainless fasteners; high-temp silicone gaskets.

Controls & Electronics

- Sensing: Inlet/outlet temps, exchanger surface temp; optional irradiance cue.

- Actuation: PWM fans/pump; safe start, watchdog, thermal cutoffs.

- MCU & Logs: Arduino Mega; SD logging; manual override + status LEDs.

Testing & Validation

- Test cell: Repeatable indoor setup; log ΔT, TEG V/I, time-to-steady-state, ambient.

- Loss audits: Insulation A_B, leak checks, mirror alignment.

- Iteration log: Issue → change → result with photos.

Interfaces & Safety

- UI: Single ON/OFF + setpoint; clear status indicator.

- Physical: Guards on hot zones; tip-resistant frame.

- Electrical: Fused input, strain relief, grounded enclosure.

Out of Scope (this iteration)

- Closed-loop refrigerants for Mars, radiation hardening, habitat-pressure integration.

Concept Development

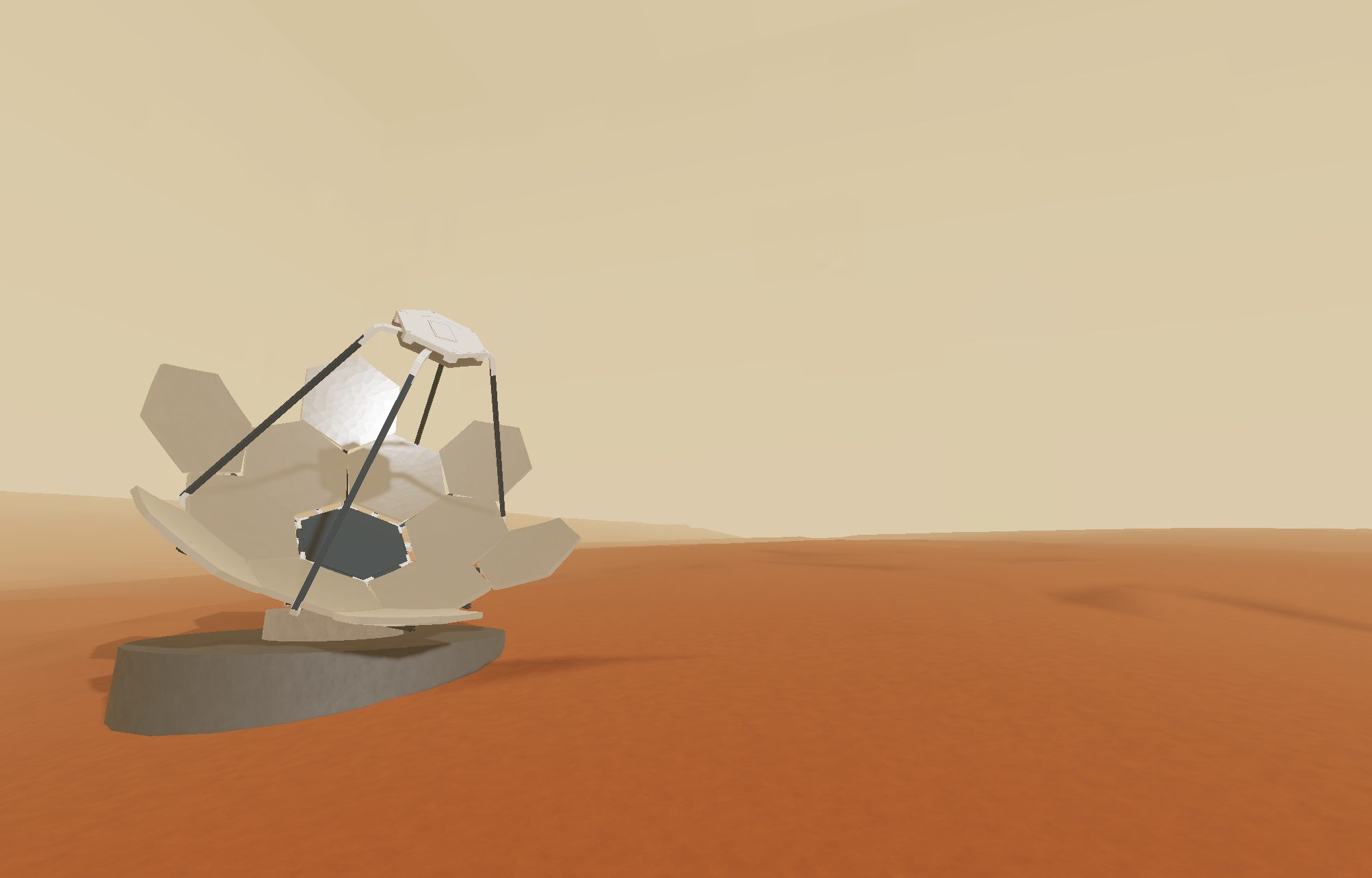

Optics Architecture

- Candidate shapes: circular, hexagonal

- Candidate curvature: parabolic, spherical

- Design chosen: parabolic hexagonal mirrors (25cm edge length)

Reasoning

- Spherical mirrors scatter light into an area known as a focal volume. [Image of spherical vs parabolic mirror focal points]

- On the other hand, parabolic mirrors focus light into a single focal point.

- This makes parabolic mirrors suitable for concentrating large amounts of light onto a single point, like, say, a small heat exchanger.

- When arranged in an array, hexagonal geometries perform better at filling gaps between mirrors, as evidenced by the James Webb Space Telescope design process.

Heat Exchanger Geometry

- Picked: Aluminum plate with spiral groove to seat 12 mm OD silicone tubing; paste + clamp pressure for contact.

- Rejected: Microchannel plate (fabrication cost), copper coil bundle (contact inconsistency, harder to mount).

- Tradeoffs: Spiral gives a predictable path, serviceable tubing, and printable fixtures.

Sun Tracking and Alignment

- 4 Light Dependent Resistors (LDRs) mounted in different quadrants feed real-time light intensity to a Microcontroller Unit (MCU).

- The MCU will create a 2x2 grid that models the current location of the sun in the sky.

- Light intensity readings are compared to known values, allowing for determining a night/day/dust storm cycle. In the event of a blackout, the motors will be locked in place and the system will enter a state of hibernation.

- Using motors + magnetic encoder feedback, the MCU will reorient the mirror array to face the sun directly.

Materials and Manufacturability

- Picked: PETG for brackets/connectors and ASA for heat-sensitive components. Future iterations will explore the use of recycled PET (rPET) plastics from mission waste.

- Rejected: High-temp exotic polymers (cost), carbon fiber layups (tooling/time).

- Picked: Aluminum foil for mirror surfaces. Future iterations will explore the use of stainless steel sheet metal.

- Rejected: reflective sprays (unrealistic for ISRU application).

Fabrication and Assembly

Printed Components

- Brackets made of PETG.

- Heat exchanger plate mount made of ASA.

- Infill was adjusted so that the most structurally taxed areas have the most strength, while the least structurally taxed areas conserve material.

- To further conserve material, no top or bottom layers were used for most components.

Machined Parts

- 2020 and 2040 aluminum extrusions were bought in bulk and cut to size, forming the frame.

- Aluminum stock material was bought and cut to size, forming heat sinks.

Optics Build

- Mirrors are printed as separate, mass-producible parts, assembled using clips or mechanical welding of the plastic.

- The surface is made of store-bought aluminum foil, mimicking resources that might be available on a Mars mission.

Custom Electronics

- I custom-designed an LDR board, featuring a built-in voltage divider, resistors, and a status LED.

- The finished board was ordered from PCBWay.

Frame Assembly

- The frame was assembled using various M4 screw variants, T-nuts, and M4 threaded inserts.